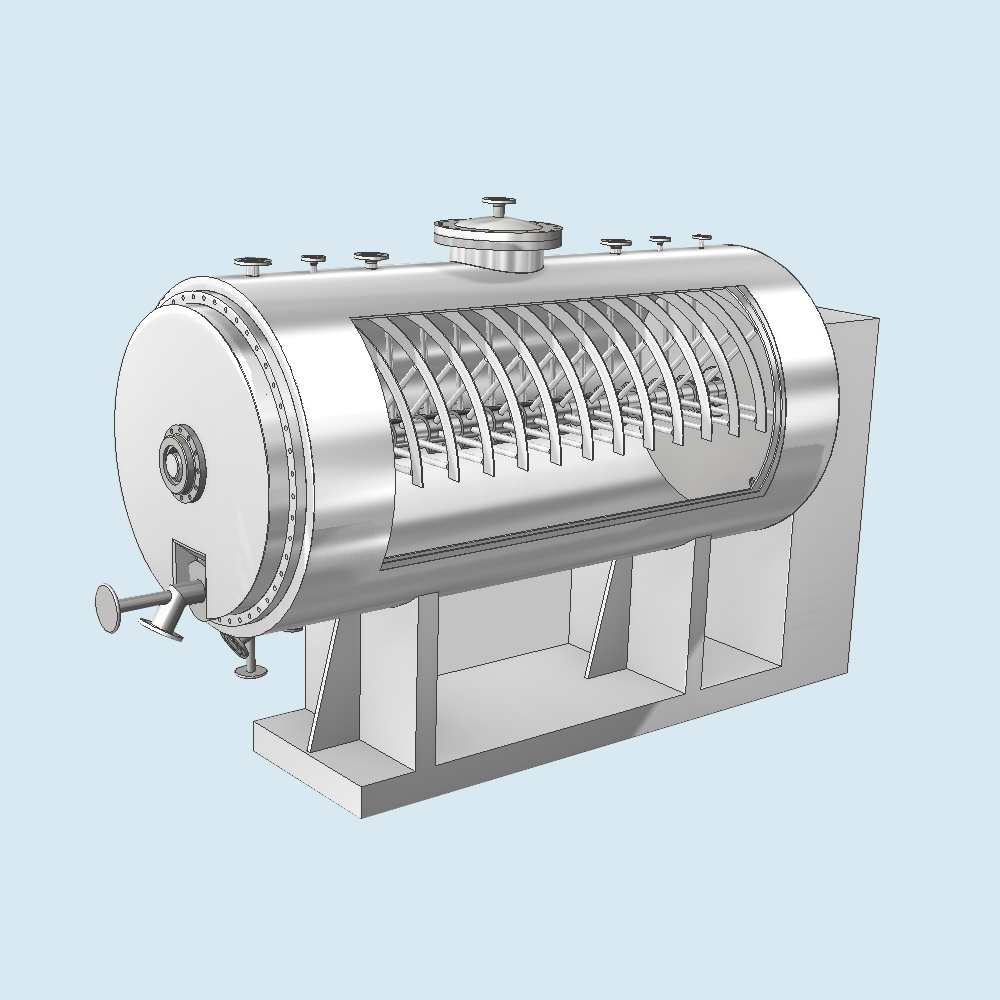

High Efficiency & Energy Saving Horizontal Crystallizer

Product Description

Working Principle

In the process of crystallization, the supersaturation of solution, uniform consistency of material temperature, stirring speed and cooling area are the decisive factors affecting grain size and appearance of the product.In order to effectively control the crystallization process and obtain satisfactory crystals, the crystallizer must have large heat transfer area, suitable stirrer structure and rotating speed, controllable cooling water temperature and reasonable empty structure in the crystallizer.

Summary

Applications and Features

Material: SS304, SS316L, Ti, Hastelloy-C, PTFE lined or other materials

Applications: refined naphthalene, borneol, Lithium Hexafluorophosphate, pharmaceutical,and also crystallization of other products.

Applications: Jacket structure is applied in this equipment that makes big cooling area available. Ribbon agitator is installed in the barrel with fast cooling speed of materials and efficient crystallization. Meanwhile, through the ribbon agitator, all the materials in the barrel can be cooled uniformly, and ensure that grains after crystallizing will have uniform size.

| Technical Parameter

| |

1. Multifunctional “Three in One” (filtering, washing and drying)

3. Sterile double-cone Dryer

4. Rake Vacuum Dryer /Paddle Vacuum Dryer

5. Plate-fin heat exchanger

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Ti/HC22/Mone11

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

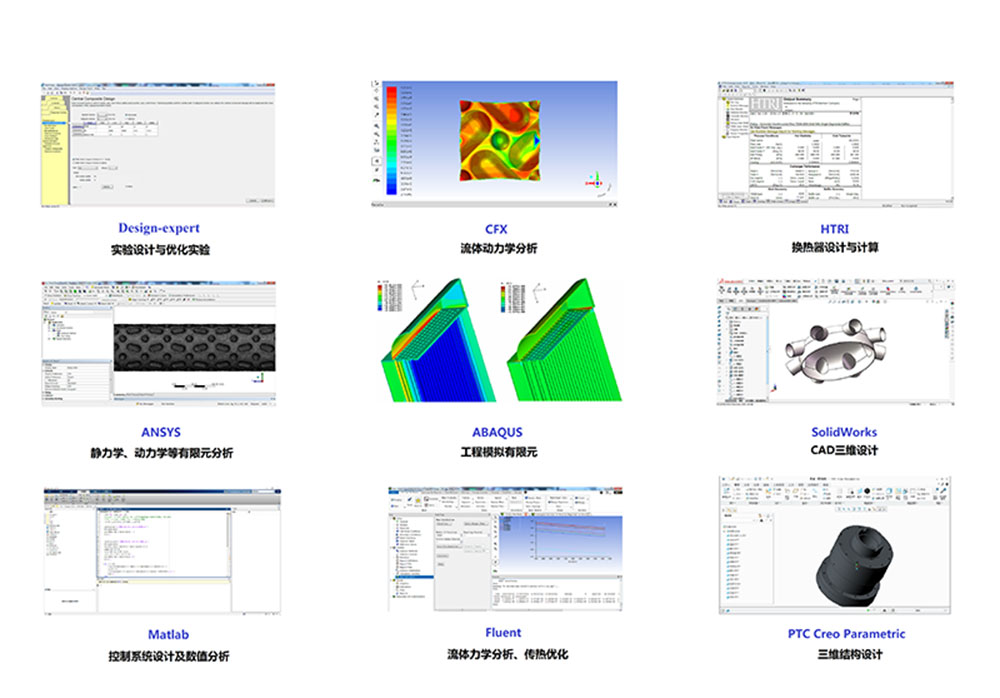

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2.Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5. On-site Testing and Training

6. Spare Parts

Product Categories : Crystallizer > Static Crystallizer