ZLG Spray Dryer for Chinese Traditional Medicine Extract

Basic Info

Model No.: ZLG

Product Description

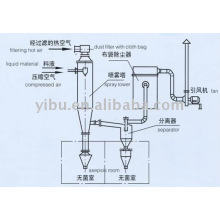

ZLG Spray Dryer for Chinese Traditional Medicine Extract Descriptions The machine adopts full seal from.All parts are made of stainless steel.It is equipped with three grades of filter.The filtered air is one hundred thousand grades.The cooling device of wall is installed at the cylinder body.It makes the wall temperature less than 80°C.Air sweeping device is installed inside the drying tower. The product will not be burnt or deteriorated even stays on the way.The collection rate of powder is raised greatly.Moreover will not cause medicine mixed or wall stick.

Basic Principle:high-speed centrifuge atomizing for the extract of traditional Chinese medicine is an application of centrifuge atomizing technique.It is an high-speed atomizing Dryer.The following problems are solved.

1.Raw material is stick to the wall and the rate of powder collecting is low.

2.Because the staying time of raw material at wall is long,the phenomenon of burnt and degenration can be produced.

3.It is difficult to clean and can not meet the requirement of GMP .

4.Low in output:Model LPG-150 atomizing centrifuge dryer can process 50-60kg/h of raw material liquid.In view of this,according to the properties and process requirements of the extract of traditional Chinese medicine,our factory researched and designed the special dryer for the extract of traditional Chinese medicine and won items of china patent.It solves the historical difficult problems in drying the extract of traditional Chinese medicine.The color of dried raw material is good.The dried raw material does not degenerate.It raises the economic benefit greatly.Compared to ordinary LPG high-speed atomizing dryer,it has the following features:

(1).Adopted three-grade air filter,the inlet air is one hundred thousand grade.

(2).Adopted wall cooling device,the temperature of inner wall will be on more than 80°C.Even if raw material is stayed on the wall,it will not be burnt.

(3).Its whole volume is 3.5 times of standard LPG high-speed atomizing dryer.

(4).Adopted quick washing device,it is can meet the requirements of production for varieties if products.

(5).Adopted wet-dedusting,there is no powder dust out.It is in conformity with the requirements of GMP.

(6).Adopted air sweeping device ,the clean effect is satisified.

(7).Equipped with two sets of atomizer and adopted frequency inverter control.

(8).Adopted PLC control and display,and adapted frequency control.

(9).Equipped with washing device on request.

(10).Adopted the seal transport by dry air on request Features 1.Tower body has air cooled jacket.

2.Tower body is equipped with automatic vibration device.

3.Tower body and pipe line have cleaning hole and sewage discharge hole that can open quickly.

4.Thermostat feeding tank on request.

5.Mannal high pressure washing machine on request.

6.The parts that can contact raw material are made of stainless steel (all entirely stainless steel).

7.The collecting of raw material adopts two grades cyclone or one-grade cyclone and one-grade wet-method-deduster.

8.The temperature of inlet air can be controlled automatically and continuously.

9.Equipped with air sweeping device on request. Technical Parameters

Contact us if you need more details on Pharmaceutical Spray Dryer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pharmaceutical Spray Dryer、Pharmaceutical Spray Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Basic Principle:high-speed centrifuge atomizing for the extract of traditional Chinese medicine is an application of centrifuge atomizing technique.It is an high-speed atomizing Dryer.The following problems are solved.

1.Raw material is stick to the wall and the rate of powder collecting is low.

2.Because the staying time of raw material at wall is long,the phenomenon of burnt and degenration can be produced.

3.It is difficult to clean and can not meet the requirement of GMP .

4.Low in output:Model LPG-150 atomizing centrifuge dryer can process 50-60kg/h of raw material liquid.In view of this,according to the properties and process requirements of the extract of traditional Chinese medicine,our factory researched and designed the special dryer for the extract of traditional Chinese medicine and won items of china patent.It solves the historical difficult problems in drying the extract of traditional Chinese medicine.The color of dried raw material is good.The dried raw material does not degenerate.It raises the economic benefit greatly.Compared to ordinary LPG high-speed atomizing dryer,it has the following features:

(1).Adopted three-grade air filter,the inlet air is one hundred thousand grade.

(2).Adopted wall cooling device,the temperature of inner wall will be on more than 80°C.Even if raw material is stayed on the wall,it will not be burnt.

(3).Its whole volume is 3.5 times of standard LPG high-speed atomizing dryer.

(4).Adopted quick washing device,it is can meet the requirements of production for varieties if products.

(5).Adopted wet-dedusting,there is no powder dust out.It is in conformity with the requirements of GMP.

(6).Adopted air sweeping device ,the clean effect is satisified.

(7).Equipped with two sets of atomizer and adopted frequency inverter control.

(8).Adopted PLC control and display,and adapted frequency control.

(9).Equipped with washing device on request.

(10).Adopted the seal transport by dry air on request Features 1.Tower body has air cooled jacket.

2.Tower body is equipped with automatic vibration device.

3.Tower body and pipe line have cleaning hole and sewage discharge hole that can open quickly.

4.Thermostat feeding tank on request.

5.Mannal high pressure washing machine on request.

6.The parts that can contact raw material are made of stainless steel (all entirely stainless steel).

7.The collecting of raw material adopts two grades cyclone or one-grade cyclone and one-grade wet-method-deduster.

8.The temperature of inlet air can be controlled automatically and continuously.

9.Equipped with air sweeping device on request. Technical Parameters

| spec | ZLG-25 | ZLG-50 | ZLG-80 | ZLG-100 | ZLG-150 | ZLG-200 | ZLG-300 | |

| evaporation capacity(kg/h) | 25 | 50 | 80 | 100 | 150 | 200 | 300 | |

| process amount of material liquid(kg/h) | 25-34 | 50-68 | 80-108 | 100-135 | 150-203 | 200-270 | 300-406 | |

| output of finished product(kg/h) | 4.8-7.2 | 9.2-14 | 14.8-22.4 | 18.4-28 | 28-42 | 36.8-56.4 | 55-85 | |

| solid content of material liquid(%) | 18-25 | |||||||

| moisture content of finished product(%) | 3-5 | |||||||

| electric powder(kw) | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |

| heat source | steam plus electricity | |||||||

| collecting method of product and its efficiency | two-grade cyclone or one-grade cyclone and one-grade web-method dedusted of 95% | |||||||

| automatic control meters and instruments | indicator of not air and exhaust air temperature | |||||||

| temperature of air inlet(°C) | 150-200 | |||||||

| temperature of air outlet(°C) | 80-100 | |||||||

| overall dimensions(mm) | L | 7000 | 8000 | 9800 | 11000 | 12200 | 14100 | 15000 |

| W | 4000 | 5000 | 5700 | 6200 | 7000 | 7800 | 9000 | |

| H | 6900 | 7400 | 8000 | 8900 | 10000 | 11000 | 12000 | |

Product Categories : Spray Drying Granulator

Premium Related Products

Other Products

Hot Products

YZG/FZG Vacuum DryerYS Series Fluid Bed Hopper Lifting Machine (Lifting machine )Vertical Fluidizing Dryer used in feedJCT Series Special Oven for pharmaceuticalGZQ Series Rectilimear Vibrating-Fluidized Drier machine for chemical industryInstant soluble capsules production linefood granule making machine(laboratory dry granulatorBall granulating machine for ceramic industrysmall wooden product for mesh-belt dryerDLB fluid bed fertilizer fluid bed coater for granulating the materialSZG Series Conical Vacuum Dryer used in leesLG series roller compactor used in tablet capsuleMini Vacuum Freeze DryerIndia Graphene Vacuum DryerLimestone flash dryerMoringa powder leaf drying machine