Hot Air Circulating Oven With Agitated

Product Description

Products Description

Material:SS304, SS316L, Hastelloy,and other material

Application:pharmaceutical, food, light, chemical and other industries.

Characteristics

➤Vacuum Dryer has a jacket to conduct heat. There is a hollow agitator which can conduct heat inside the vessel, and this agitator rotatesclockwise and anticlockwise, then the material inside the vessel will fullaccp/ heated during forced mixing, speeding up the evaporation, andtake away the steam through vacuuming to dry.

➤The equipment has bigger area for conducting heat,( 58495079,Compared with the double-cone Rotary Vacuum Dryer, it has over 1/3 more areas for conducting heat, with 70% loading capacity, 50% drying time less). It has high heat conduction coefficient, small covering area, and lots of other advantages.

Product Details

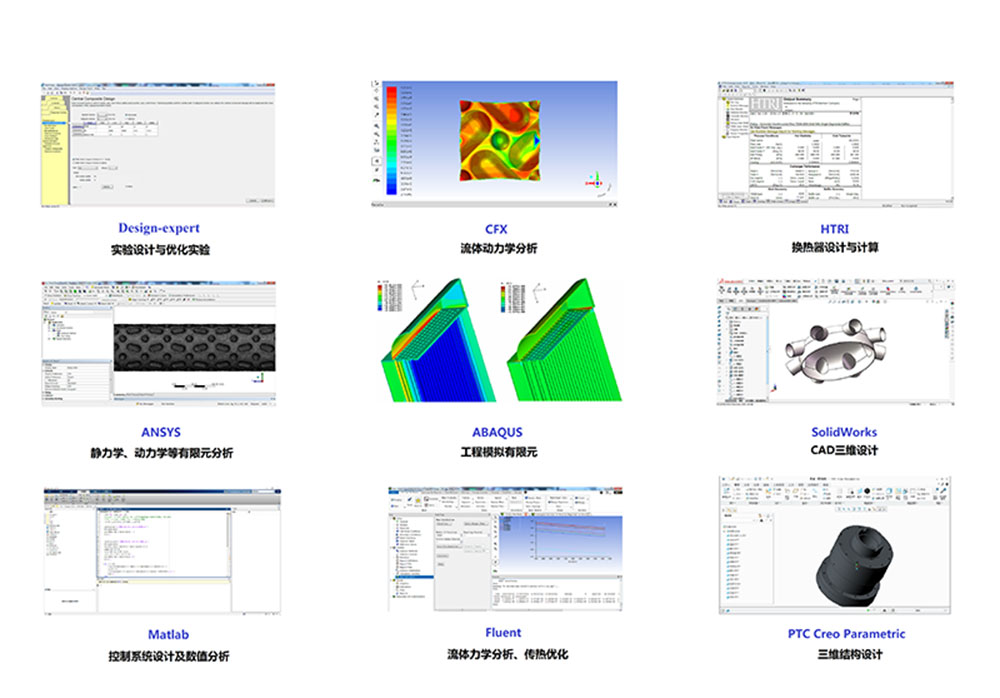

Design / Calculation Software

Custom Service

➤Our Products for pharmaceutical and chemical industries

1. Multifunctional “Three in One” (filtering, washing and drying)

1. Multifunctional “Three in One” (filtering, washing and drying)

2. Crystallizing Tank, Reaction Kettle

3. Sterile double-cone Dryer

4. Rake Vacuum Dryer /Paddle Vacuum Dryer

5. Plate-fin heat exchanger

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials,

3. Sterile double-cone Dryer

4. Rake Vacuum Dryer /Paddle Vacuum Dryer

5. Plate-fin heat exchanger

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials,

Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

Ti/HC22/Mone11

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2.Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5. On-site Testing and Training

6. Spare Parts

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

Ti/HC22/Mone11

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2.Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5. On-site Testing and Training

6. Spare Parts

Company Profile

Product Categories : Vacuum Drying Equipment > Hot air system

Hot Products

YZG/FZG Vacuum DryerYS Series Fluid Bed Hopper Lifting Machine (Lifting machine )Vertical Fluidizing Dryer used in feedJCT Series Special Oven for pharmaceuticalGZQ Series Rectilimear Vibrating-Fluidized Drier machine for chemical industryInstant soluble capsules production linefood granule making machine(laboratory dry granulatorBall granulating machine for ceramic industrysmall wooden product for mesh-belt dryerDLB fluid bed fertilizer fluid bed coater for granulating the materialSZG Series Conical Vacuum Dryer used in leesLG series roller compactor used in tablet capsuleMini Vacuum Freeze DryerIndia Graphene Vacuum DryerLimestone flash dryerMoringa powder leaf drying machine