LZG Screw Vibrating Dryer used in chemical

Basic Info

Model No.: LZG

Product Description

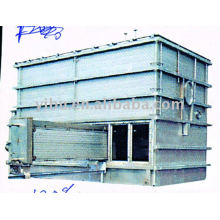

LZG Screw Vibrating Dryer Features: Features for LZG Screw Vibrating Dryer as bellow: Because the hot air passes through the layer of raw material several tiers and acts counter motion towards the raw material, the heat exchanger is fully preferment and thermal efficiency is high.

The structure is compact and it occupies small area.

The stay time of raw material in thehelix bed can be adjusted and the operation is very convenient

The raw material acts the motion if circle at helix bed from up to low, at the same the equipment can jump itself, so the contact surface between hot air and raw material is increased too and the dry effects is strengthened.

The equipment is suitable for continuous operation because of continuous feeding and discharging raw material .Meanwhile it is easy to meet the requirements of "GMP"

It does not damage the surface and shape of raw material basically. It can not only maintain the roundness of pill but also decrease the rate of pills. LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer Principle: The principle for LZG Screw Vibrating Dryer as bellow: The wet raw material enters into helix bed from fed inlet at the top and moves along with the helix bed from up to low and make jumping to the bottom, under the effect of vibrating force and gravity and then it's discharger. Meanwhile clean hot air enters into it from the bottom of helix bed and carries out heat exchange with raw material on the helix bed fully and exhausts from the outlet at the top. In this way the dry purpose of wet raw material is realized. LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer Technical parameters:

LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer Contact us if you need more details on Screw Vibrating Dryer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Vibrating Dryer、Screw Vibrating Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

The structure is compact and it occupies small area.

The stay time of raw material in thehelix bed can be adjusted and the operation is very convenient

The raw material acts the motion if circle at helix bed from up to low, at the same the equipment can jump itself, so the contact surface between hot air and raw material is increased too and the dry effects is strengthened.

The equipment is suitable for continuous operation because of continuous feeding and discharging raw material .Meanwhile it is easy to meet the requirements of "GMP"

It does not damage the surface and shape of raw material basically. It can not only maintain the roundness of pill but also decrease the rate of pills. LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer Principle: The principle for LZG Screw Vibrating Dryer as bellow: The wet raw material enters into helix bed from fed inlet at the top and moves along with the helix bed from up to low and make jumping to the bottom, under the effect of vibrating force and gravity and then it's discharger. Meanwhile clean hot air enters into it from the bottom of helix bed and carries out heat exchange with raw material on the helix bed fully and exhausts from the outlet at the top. In this way the dry purpose of wet raw material is realized. LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer/LZG Screw Vibrating Dryer Technical parameters:

| spec | LZG-1.0 | LZG-1.2 | LZG-1.4 | LZG-1.6 | LZG-1.8 |

| diameter(mm) | 1000 | 1200 | 1400 | 1600 | 1800 |

| power(kw) | 2×0.75 | 2×0.75 | 2×1.5 | 2×1.5 | 2×2.2 |

| Overall dimension (m) | 1.2×1.2×2.7 | 1.4×1.4×2.7 | 1.6×1.6×3.3 | 1.8×1.8×3.3 | 2.0×2.0×3.3 |

| weight(kg) | 1400 | 1680 | 2800 | 3100 | 3800 |

| production capacity(kg/h) | 80120 | 120200 | 200280 | 280350 | 350450 |

| temperature of air inlet( ) | 60200 | 60200 | 60200 | 60200 | 60200 |

| air amount(m3/h) | 1487 | 2380 | 3721 | 4462 | 5930 |

| Poweer of fam(kw) | 5.5 | 7.5 | 15 | 18.5 | 22 |

Product Categories : food production line

Premium Related Products

Other Products

Hot Products

YZG/FZG Vacuum DryerYS Series Fluid Bed Hopper Lifting Machine (Lifting machine )Vertical Fluidizing Dryer used in feedJCT Series Special Oven for pharmaceuticalGZQ Series Rectilimear Vibrating-Fluidized Drier machine for chemical industryInstant soluble capsules production linefood granule making machine(laboratory dry granulatorBall granulating machine for ceramic industrysmall wooden product for mesh-belt dryerDLB fluid bed fertilizer fluid bed coater for granulating the materialSZG Series Conical Vacuum Dryer used in leesLG series roller compactor used in tablet capsuleMini Vacuum Freeze DryerIndia Graphene Vacuum DryerLimestone flash dryerMoringa powder leaf drying machine